An automatic rotary capping machine is a type of automated equipment used for applying caps to bottles, jars, or other containers in high-speed production lines. The machine works by using a rotating turret or carousel that moves the containers through different stages of the capping process.

At the capping station, the machine uses a variety of capping mechanisms, such as torque control, snap-on, or screw-on, to apply the cap to the container. The machine can be programmed to handle different types and sizes of caps and containers, and it can be adjusted to accommodate different production rates and cap tightness specifications.

One of the advantages of an automatic rotary capping machine is its high level of efficiency and accuracy. The machine can cap hundreds or even thousands of containers per hour, reducing the need for manual labor and minimizing the risk of human error. Additionally, the machine's precision torque control can ensure consistent and secure cap application, which is critical for maintaining product integrity and preventing leaks or contamination.

The automatic rotary capping machine can also be integrated with other packaging equipment, such as fillers, labelers, and conveyors, to create a complete packaging system that can handle all aspects of the packaging process. This integration can further enhance the machine's efficiency and streamline the production process.

Overall, the automatic rotary capping machine is a reliable and cost-effective solution for manufacturers looking to increase their production rates, improve product quality, and reduce labor costs in their capping process.

Deskripsi Produk

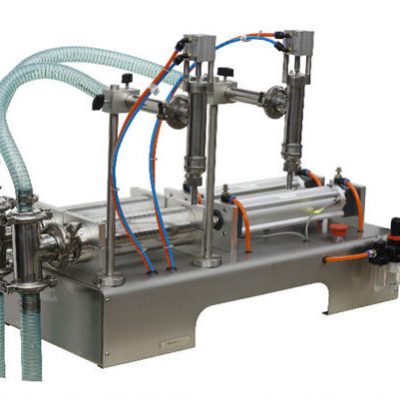

Mesin Capping Rotary Otomatis

Karakter produk

Mesin Rotary Capping Otomatis dirancang khusus oleh tim Neostarpack dan mengadopsi motor fase tunggal yang ringkas dan memiliki tenaga kuda yang hebat.

Mesin Capping Rotary Otomatis

fitur

1. Tekanan penyegelan dapat disesuaikan oleh torsi sesuai untuk berbagai topi.

2. Dikendalikan oleh sistem PLC dengan layar sentuh, mudah dibaca dan dioperasikan.

3. Tidak ada botol, tidak ada penutup.

4. Putar roda terputus-putus untuk memastikan posisi botol yang tepat.

5. Parameter memori untuk pergantian cepat.

6. Konveyor rantai atas tugas berat stabil dan tahan lama.

7. Kepala penyegelan halus membuat capping tepat.

8. Topi hopper membuat topi jatuh dan meluruskan secara otomatis.

9. Putar roda dan kepala segel dapat diganti-ganti.

10. Dilengkapi dengan karet di bagian bawah untuk mengurangi kerusakan tutup.

Spesifikasi

| Jenis topi: | semua jenis topi |

| Diameter topi: | 22 ~ 120 mm |

| Kecepatan capping: | 30 ~ 40 botol / menit |

| Persyaratan tekanan udara: | 6kg |

| Sumber Daya listrik: | 110V atau 220VAC, 50 / 60Hz |

Mesin Capping Rotary Otomatis

Aksesori opsi

1. Feeding tray

2. Low storage and missing caps detective system

3. Customized rotate wheel

Rincian Cepat

Jenis: Mesin Capping

Kondisi: Baru

Aplikasi: Makanan, Minuman, Komoditas, Medis, Kimia, Mesin & Perangkat Keras

Tipe Didorong: Listrik

Kelas Otomatis: Otomatis

Daya: 110v atau 220vac

Jenis Kemasan: Peti

Bahan Kemasan: Kayu

Tempat Asal: Shanghai Cina

Nama Merek: VKPAK