Mesin pengisian & penutup roda bintang putar otomatis kami cocok untuk mengisi produk-produk yang setipis air hingga sedang, seperti obat cair, toner, lotion perm, pengharum ruangan, perawatan kulit, dll. penampilan bagus, penyesuaian mudah dan penerapan luas, yang membuat mereka dapat digunakan secara luas di bidang farmasi, pestisida, bahan kimia sehari-hari, makanan atau industri lainnya.

Dalam seri ini, tindakan pengisian dan pembatasan didorong oleh transmisi mekanis yang akurat, yang dapat menjamin kualitas produk secara efektif. Semua stasiun kerja, termasuk mengisi, memberi makan topi, capping dilengkapi sekitar satu roda bintang, sehingga ruang kerja dan operator yang dibutuhkan dapat sangat berkurang. Mode produksi otomatis dan tanpa gangguan dapat membantu menjamin volume produksi yang Anda butuhkan. Kami memilih bahan dan bagian yang baik untuk merakit mesin kami. Semua bagian bersentuhan dengan produk-produk yang terbuat dari stainless steel food grade yang diimpor, dan semua bagian pneumatik dan listrik adalah produk merek terkenal dari Jerman, Jepang atau Taiwan. Ini adalah desain inovasi dan suku cadang berkualitas yang memastikan seri mesin ini menempati posisi terdepan di pasar kemasan cair domestik.

Mesin Pengisian dan Capping Roda Rotary Star kami terutama cocok untuk memproduksi satu jenis produk dalam batch besar produksi.

Aliran produksi:

Mengisi --- Feeding Sisipan --- Sisipan Menekan --- Feeding Caps --- Capping

Desain sesuai dengan kebutuhan Anda.

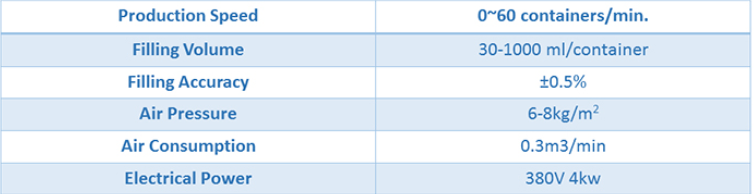

Spesifikasi Teknis Utama

Rincian Cepat

Jenis: Mesin Capping, Mesin pengisian dan pembatasan

Kondisi: Baru

Aplikasi: Minuman, Kimia, Makanan, Mesin & Perangkat Keras, Medis, Kosmetik, Kedokteran, Kimia, dll.

Tipe Didorong: Listrik dan Pneumatik

Kelas Otomatis: Otomatis

Tegangan: 380V

Daya: 4kw

Jenis Kemasan: Botol

Bahan Kemasan: Kaca, Logam, Plastik

Tempat Asal: Shanghai, Cina (Daratan)

Nama Merek: VKPAK

Dimensi (L * W * H): 1670 * 1350 * 1675

Berat: 600kg

Sertifikasi: ISO9001

Layanan Purna Jual Disediakan: Insinyur tersedia untuk melayani mesin di luar negeri

Sistem Kontrol Kualitas: ISO9001: 2008

Sistem Manajemen di Tempat: 5S

An automatic cream filling and capping machine is a highly advanced packaging machine that is specifically designed to package creams and lotions into various types of containers such as jars, bottles. This machine is essential for businesses in the cosmetics industry who want to streamline their packaging process and increase their productivity.

One of the key benefits of an automatic cream filling and capping machine is its ability to fill and cap containers at a high speed. This is achieved through the use of advanced automation technology that allows for fast and accurate filling and capping. In addition, the machine is highly versatile and can handle a wide range of container sizes and shapes, making it ideal for businesses with diverse product lines.

The machine works by first filling the containers with the cream or lotion using a dosing pump that accurately dispenses the required amount of product. The containers are then capped using a capping head that tightly seals the product to ensure freshness and prevent spillage. The capping head can be customized to accommodate different types of caps such as screw caps, flip-top caps, and snap-on caps.

One of the key features of an automatic cream filling and capping machine is its ease of use. The machine is equipped with a user-friendly control panel that allows for easy adjustment of settings such as filling volume, capping torque, and speed. This makes it easy for operators to set up and operate the machine, reducing the risk of errors and improving overall efficiency.

Another important feature of an automatic cream filling and capping machine is its high level of hygiene. The machine is designed to be easy to clean and sanitize, with smooth surfaces and minimal crevices that can trap dirt and bacteria. This is particularly important in the cosmetics industry, where hygiene is essential for ensuring product quality and safety.

In conclusion, an automatic cream filling and capping machine is a valuable investment for businesses in the cosmetics industry. With its advanced automation technology, versatility, ease of use, and high level of hygiene, this machine can help businesses increase their productivity, improve their packaging quality, and stay ahead of the competition. When choosing a cream filling and capping machine, it is important to consider factors such as production capacity, container size and shape, and the type of cream or lotion being packaged.