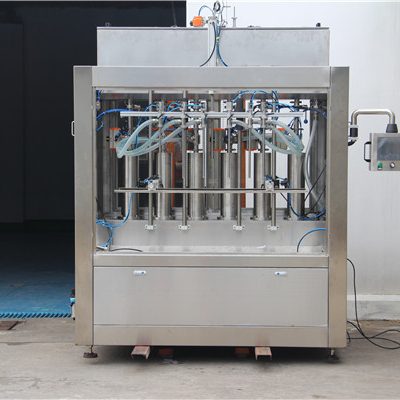

Deskripsi Produk

Teknologi baru mesin pengisian minyak otomatis

1. Mesin kerangka utama dari mesin pembuat minyak mengadopsi teknologi kontrol otomatis PLC dan transduser dengan otomatisasi tingkat tinggi.

2. Sistem dinamis dari mesin pembuat minyak dihubungkan oleh poros transmisi dengan kinerja yang stabil.

3. Prinsip pengisian gravitasi negatif mikro meningkatkan presisi.

4. Sistem pelumasan otomatis canggih yang dilengkapi dengan mesin pembuat minyak tidak memerlukan upaya manual dan meningkatkan masa pakai mesin.

5. Kebisingan mesin pembuat minyak rendah dan keseluruhan mesin mudah dirawat.

Parameter teknik

Model | Mencuci kepala, mengisi kepala dan menutup kepala | Kapasitas produksi (botol per jam untuk 500ml) | Spesifikasi botol yang berlaku (mm) | Daya motor utama (kw) |

| VKPAK-14-12-5 | 14,12,5 | 4000BPH | 200ml-2500ml D = 55-110mm H = 150-310mm | 1.5 |

| VKPAK 16-16-5 | 16,16,5 | 5500BPH | 2.2 | |

| VKPAK 24-24-6 | 24,24,6 | 8000BPH | 2.2 | |

| VKPAK32-32-8 | 32,32,8 | 10000BPH | 3 | |

| VKPAK40-40-10 | 40,40,10 | 14000BPH | 5.5 | |

| NAPCK50-50-12 | 50,50,12 | 17000BPH | 5.5 | |

| VKPAK60-60-15 | 60,60,15 | 20000BPH | 7.5 | |

| VKPAK72-72-18 | 72,72,18 | 25000BPH | 7.5 |

Rincian Cepat

Jenis: Mesin Pengisian

Kondisi: Baru

Aplikasi: Minyak

Jenis Kemasan: Botol

Bahan Kemasan: Kayu

Kelas Otomatis: Otomatis

Tipe Didorong: Listrik

Tegangan: 380v

Daya: 7.5kw

Tempat Asal: Shanghai, Cina (Daratan)

Nama Merek: VKPAK

Model Number: VKPAK32-32-8 New technology automatic oil filling machine, VKPAK32-32-8

Dimensi (L * W * H): 4600x1800x2650mm

Berat: 9000kg

Sertifikasi: ISO, CE, SGS, ISO, CE, SGS

Layanan Purna Jual Disediakan: Insinyur tersedia untuk melayani mesin di luar negeri

Nama: Teknologi baru mesin pengisian minyak otomatis

Kapasitas: 20000BPH

Daya Motor Utama: 7.5kw

Botol yang Berlaku: D = 55-110mm H = 150-310mm

Garansi: 2 tahun

Bahan Mesin: SUS304

Kemasan & Pengiriman

Rincian Kemasan:

kasus kayu standar untuk teknologi Baru mesin pengisian minyak otomatis

Rincian pengiriman:

45 hari untuk mesin pengisian minyak otomatis teknologi baru

Spesifikasi

Teknologi baru mesin pengisian minyak otomatis

1. capacity:4000-25000BPH(500ml)

2. guarantee:2 years

3. high quality, good price

An 8000BPH (bottles per hour) automatic coconut oil filling machine line is a high-speed bottling system designed for the efficient and accurate filling of coconut oil into containers. This type of filling machine typically consists of several components, including an unscrambler, bottle washing machine, filling machine, capping machine, labeling machine, and packaging machine. The overall production line is designed to work together seamlessly to achieve a high rate of production while ensuring that the quality and accuracy of the fill is maintained.

The specific features and specifications of an 8000BPH coconut oil filling machine line may vary depending on the manufacturer and the intended application, but some common features include:

High-speed production: This type of machine is designed to fill containers at a high rate of speed, with the capability of filling up to 8000 bottles per hour.

Precision filling: A sophisticated control system and precise filling nozzle ensure that each bottle is filled to the exact volume specified, with minimal waste.

Adaptability: Many coconut oil filling machine lines are designed to be adaptable to different bottle sizes and shapes, allowing for easy changeover and minimal downtime.

Quality control: A variety of sensors and inspection systems are integrated into the production line to ensure that the filling and capping processes meet the necessary quality standards.

Ease of use: The machines in a coconut oil filling machine line are typically designed with user-friendly controls and intuitive operation, making them easy to set up and operate.

Overall, an 8000BPH automatic coconut oil filling machine line is a reliable and efficient solution for bottling coconut oil, with the capability of achieving high production rates while maintaining a high level of accuracy and quality control.